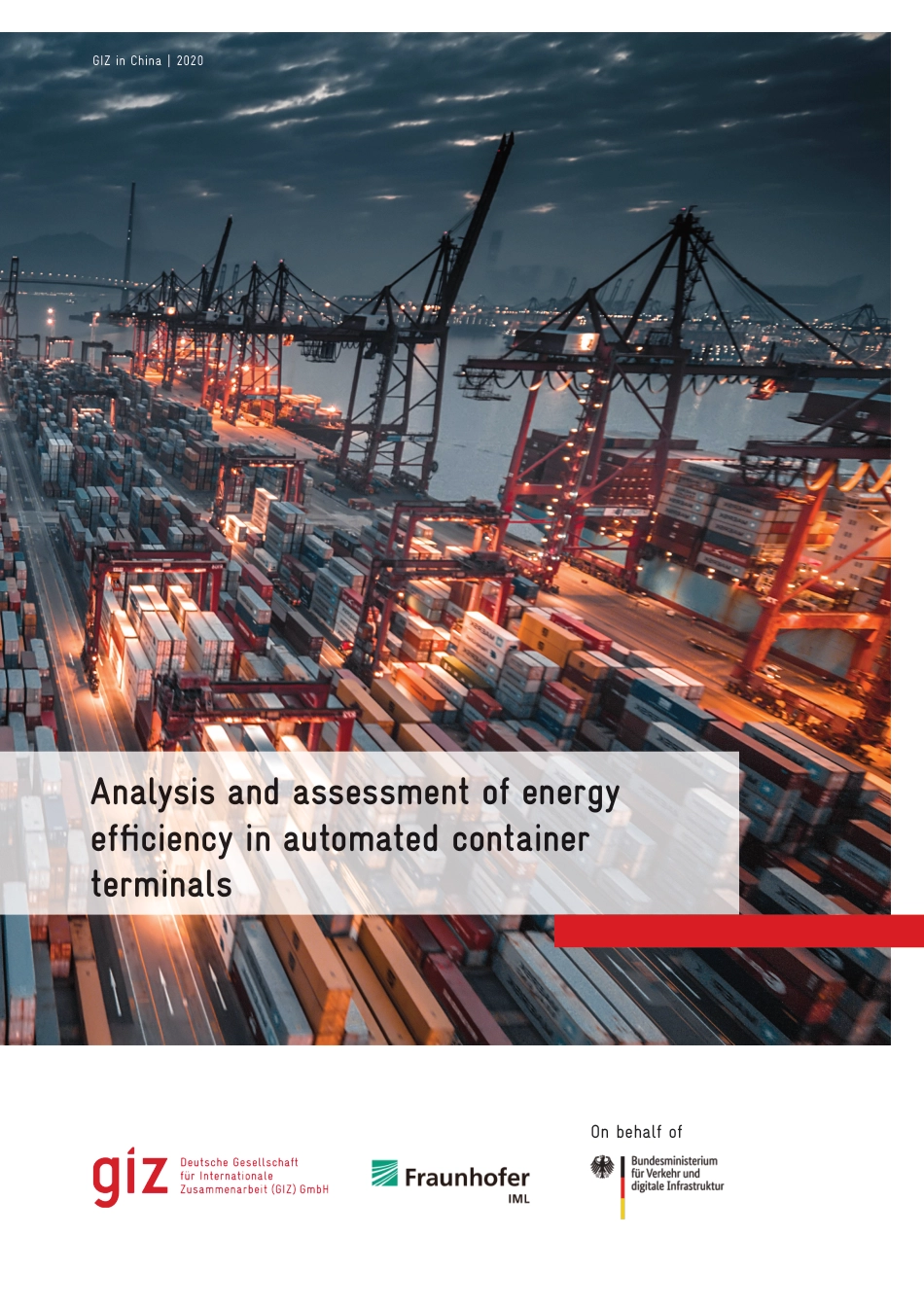

On behalf ofGIZ in China | 2020Analysis and assessment of energyefficiency in automated containerterminalsPublication DataPublished by:Deutsche Gesellschaft fürInternationale Zusammenarbeit (GIZ) GmbHRegistered offices:Bonn and EschbornAddress GIZ in China:Sunflower Tower, Room 1100 Maizidian St. 37, Chaoyang District, 100125 Beijing, PR China T +86 1085275180 F +86 1085275185E transition-china@giz.org, giz-china@giz.deI giz.de, I mobility.transitionchina.orgProject: Mobility and Fuels Strategy (MFS) as a Contribution to the Traffic Transition in China - Pilot project in the Jing-Jin-Ji regionSino-German Cooperation on Mobility and Fuels Strategy (MFS) as a Contribution to the Mobility and Transport TransitionResponsible:Alexander von Monschaw, GIZ in Chinaalexander.monschaw@giz.deAuthor:Frauenhofer IML - Achim Klukas, Nils Gastrich, Dorothe GörtzLayout and Editing:Elisabeth Kaufmann, GIZ in ChinaPhoto credits:Cover - Timelab Pro / unsplash.comURL links:This publication contains references to external websi-tes. The respective provider is always responsible for the content of the external pages listed. When it was first referred to, GIZ checked the third-party content to deter-mine whether it might trigger civil or criminal liability. A permanent control of the content of the links to external sites is not reasonable without concrete evidence of an in-fringement. If GIZ determines or is informed by others that an external offer to which it has referred triggers civil or criminal liability, it will immediately remove the reference to this offer. GIZ expressly dissociates itself from such content.On behalf of the German Federal Ministry of Transport and Digital Infrastructure (BMVI)GIZ is responsible for the content of this publication...