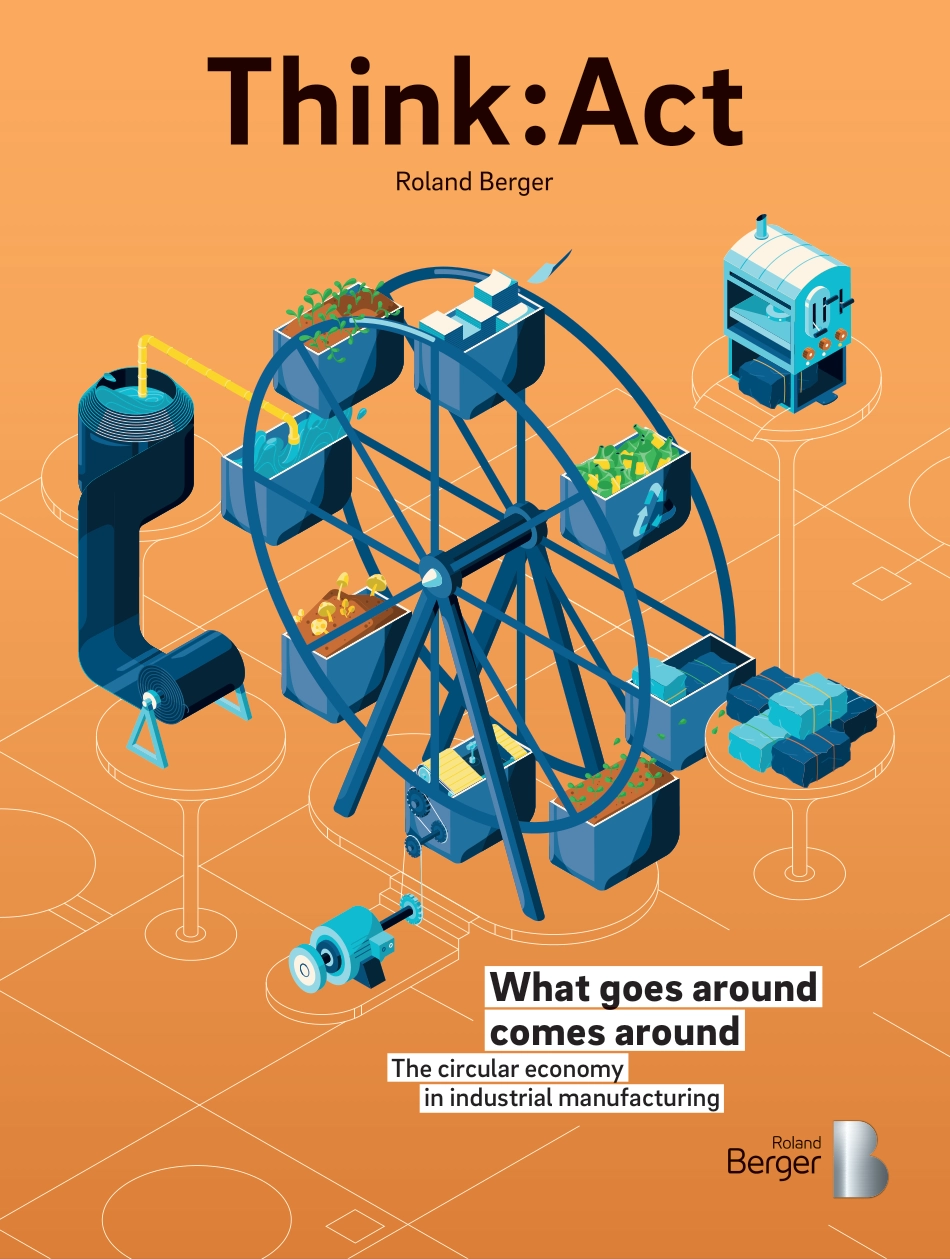

What goes aroundcomes aroundThe circular economy in industrial manufacturingTHE BIGCircularity is the keyCOMPANIES MAKE AMBITIOUS STATEMENTS ON DECARBONIZATIONReusing, repairing and refurbishingcan change the worldSecondary materials are the answerMany resources are already scarceCIRCULARITY MEANS MORE THAN JUST RECYCLING WASTEContents1 – PAGE 4 What is the circular economy – And why is it so important for industrial manufacturers? 2 – PAGE 8 The technical cycle – Four levers for changing the world PAGE 15 Interview with Andrew Morlet 3 – PAGE 17 What can we do? Real-life examples of circularity 4 – PAGE 21 The impact on business – How the circular economy affects industrial manufacturers 5 – PAGE 22 A task for the whole company – To do's by business function PAGE 24 In conclusion – A checklist for decision makersCover illustration and illustrations on page 10/11, 15-18: Studio Muti/Folio ArtThe circular economy in industrial manufacturing | Think:Act 3BACK IN 1966, renowned English-born American economist Kenneth E. Boulding described the closed economy of the future as a spaceman economy, one in which the Earth "has become a single spaceship, without unlimited reservoirs of anything, either for extraction or for pollution […]." He contrasted this with the cowboy economy of the past, in which resources appeared infinite and illimitable.The evidence is clear that we have now entered this new economic phase: Unless we clean up our act urgently and stop acting like cowboys, we will soon have to abandon ship and search for a new planet. Today, 91 percent of material flows in the economy are linear, meaning that they are mined, used and disposed of in a single flow. Our unidirectional produc...